Production and Processing

Black tea, also known as the regular tea, forms up approximately the two third of the world tea consumption. Black tea production is classified as either the official orthodox method, or the unofficial unorthodox method of CTC (Crush, Tear, and Curl).

The procedure of producing black tea through the orthodox method is as follows:

- Picking

- Wilting

- Bruising

- Fermentation (oxidation)

- Drying

- Sorting

1. Picking the green tea leaves at the farms of tea bushes

The fresh tea leaves are plucked from the bushes at our tea gardens closely monitored by our team of professional experts. Every “two leaves and a bud” are in one batch of plucking; a combination which is referred to as the most delicate part of the bush producing the best quality tea product. Our tea gardens are protected with biological pesticides where no chemical fertilizer or toxic agent is used. The garden choice and the picking method is the greatest advantage of the Zubin Tea in comparison with other tea products available on the market, which can improve people’s health.

2. Wilting

2. Wilting

Wilting is the first stage in the process of tea production. The moisture of the tea leaves is pulled out at this stage so that the leaves are ready for the bruising and oxidation stages.

The green leaf is automatically sent to the wilting room after they are carefully quality controlled by experienced experts. The tea is carried on narrow and long belts with low height. Sucking fans blow heat towards the cancellated netlike belts so that the tea leaves are wilted (dried out). The wilting stage causes physical changes (demoisturized, losing brittleness, and increasing the density of the substances inside the leaf) as well as chemical ones (stimulating the polyphenylene oxidize enzyme, decomposition of the protein in the leaf into the amino acids, decomposition of chlorophyll, etc.) in the leaves.

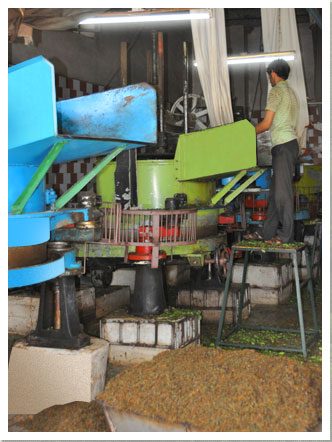

3. Bruising

3. Bruising

Bruising the green tea leaves taking place after the wilting stage includes:

First: destroying the cell and rolling the leaves so that some of the leaf juices are released.

Second: facilitating the oxidation due to the exposure to the air and the release of diastase which is a chemical in the leaf and is a kind of oxidize known as teaz. In this process, the essence of the leaf or the content of the cell is preserved after wilting and drying so that when brewing the tea, the color and the taste is at the most pleasant level.

4. Fermentation (oxidation)

4. Fermentation (oxidation)

Oxidation (absorbing the oxygen in the air) is a necessary stage in the process of tea production, and it is the last chemical process following bruising. This process starts at the bruising stage and completes at this stage. The drying of the tea is stabilized (stopped) at the fermentation stage.

The oxidation stage is a very sensitive and important chemical process which is given a lot of importance at Zubin Tea. The experts of Zubin Tea are very well aware of the fact that a few minutes delay or rush in stopping the oxidation will have a great effect in the quality, smell, color, and the taste of the tea.

5. Drying

5. Drying

Unlike the previous stages of picking, wilting, fermentation in which the green leaf is involved, the drying stage is in fact finishing the oxidation process, and preserving and stabilizing the specifications created in the leaf. The processed tea must be dried so that it does not change and delivers the quality aimed for. Two procedures are done at the drying stage. One is warming the leaf, and the other is drying it.

6. Sorting and classifying the tea

6. Sorting and classifying the tea

The produced tea is sorted, also referred to as classified, according to the size. Different sorted teas have different names and their provision on the market is based on these terms indicating the specifications of the tea.

Different types of tea

Different types of tea

- OP (Orange Pekoe): large – usually whole leaf or large cut

- OPS: relatively large

- FBOP (Broken): moderate size

- BOPI (Powdery): small

- Flower: The best produced tea regarding the benefits, color, smell, and taste.

- Dust

Furthermore, observing the hygiene and health principles in the production environment is one of the main principles of Zubin Tea.